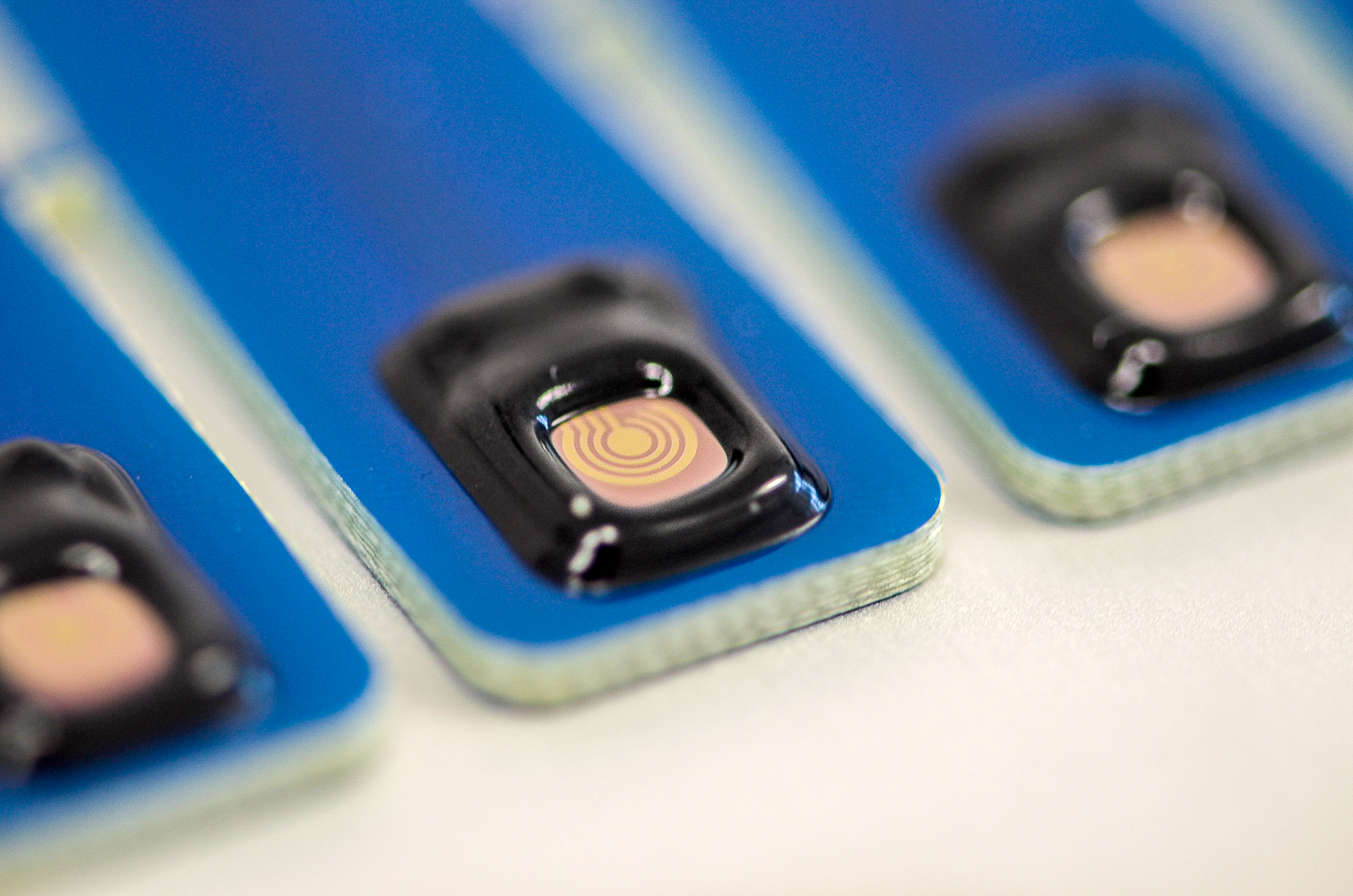

Hyperspectral imaging inspection tool for efficient semiconductor production

Together with DIVE Imaging Systems GmbH, we are working in the GreenICT Space of the GreenICT@FMD competence center on the introduction of hyperspectral imaging technology as a screening tool for semiconductor production. The aim is to make production processes more efficient and sustainable by detecting defects at an early stage and conserving resources. This not only improves environmental compatibility, but also reduces the costs of semiconductor production. The project shows how sustainable solutions in microelectronics can be realized through innovative technologies and cooperation.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems