We offer a state-of-the-art, fully integrated and CMOS-compatible ME(O)MS-on-CMOS line.

Our cleanroom, with its qualified team and industry-oriented facilities, is ideally positioned for research and development in the field of MEMS and MOEMS devices. In addition to a deep understanding of state-of-the-art MEMS manufacturing processes, coupled with modern fab technology, we are the perfect partner for technology and device development.

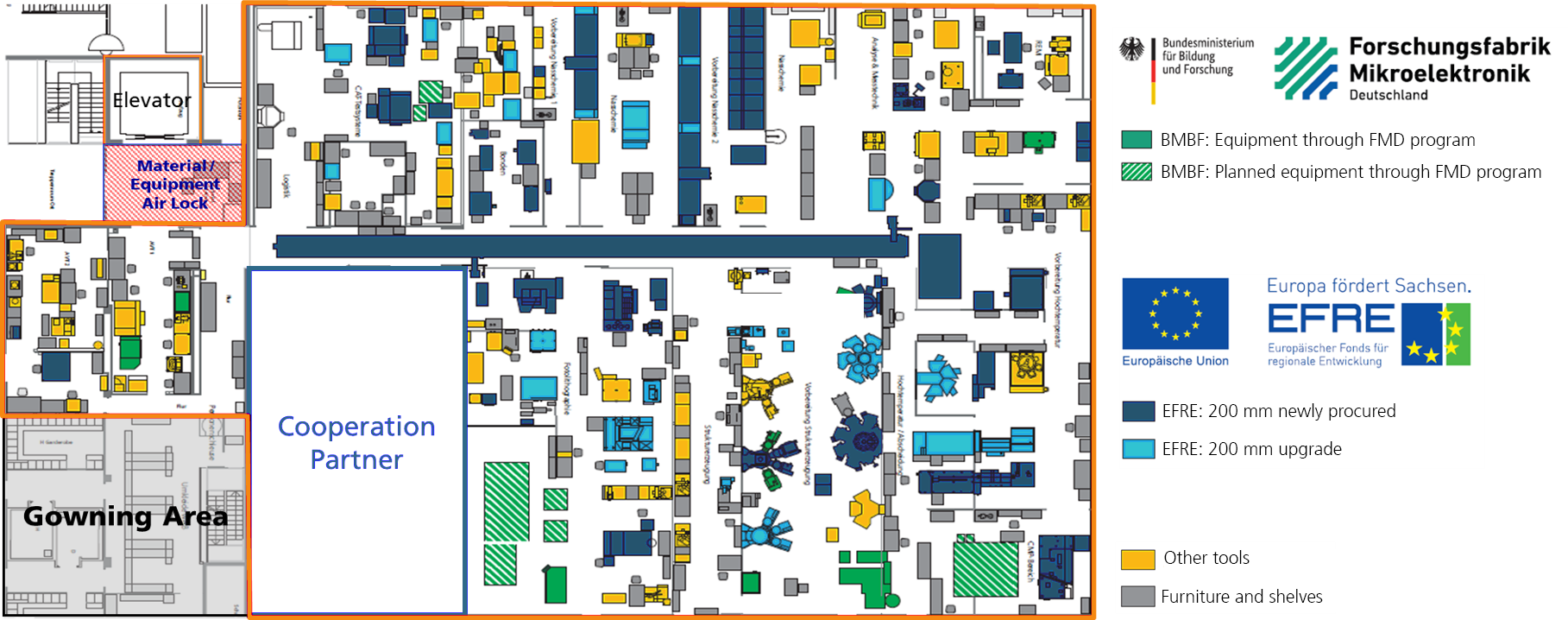

Our cleanroom at a glance:

- Low volume & high mix

- Operation 24/5 in 3 shifts

- 45 engineers + 45 operators and maintenance technicians

- ~1,000 wafer starts per month

- CMOS compatibility

- Class 10 (ISO 4) on 1,500 m²

- Certification according to ISO 9001:2015

- MES for planning, traceability and documentation

- i-line (400nm L&S) and DUV cluster (130nm L&S)

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems