Wafer processes in our 200 mm cleanroom - precision and innovation

In our state-of-the-art 200 mm clean room, we offer comprehensive wafer processes that are tailored to the individual needs of our customers. We use our flexible and industry-compatible process line for this.

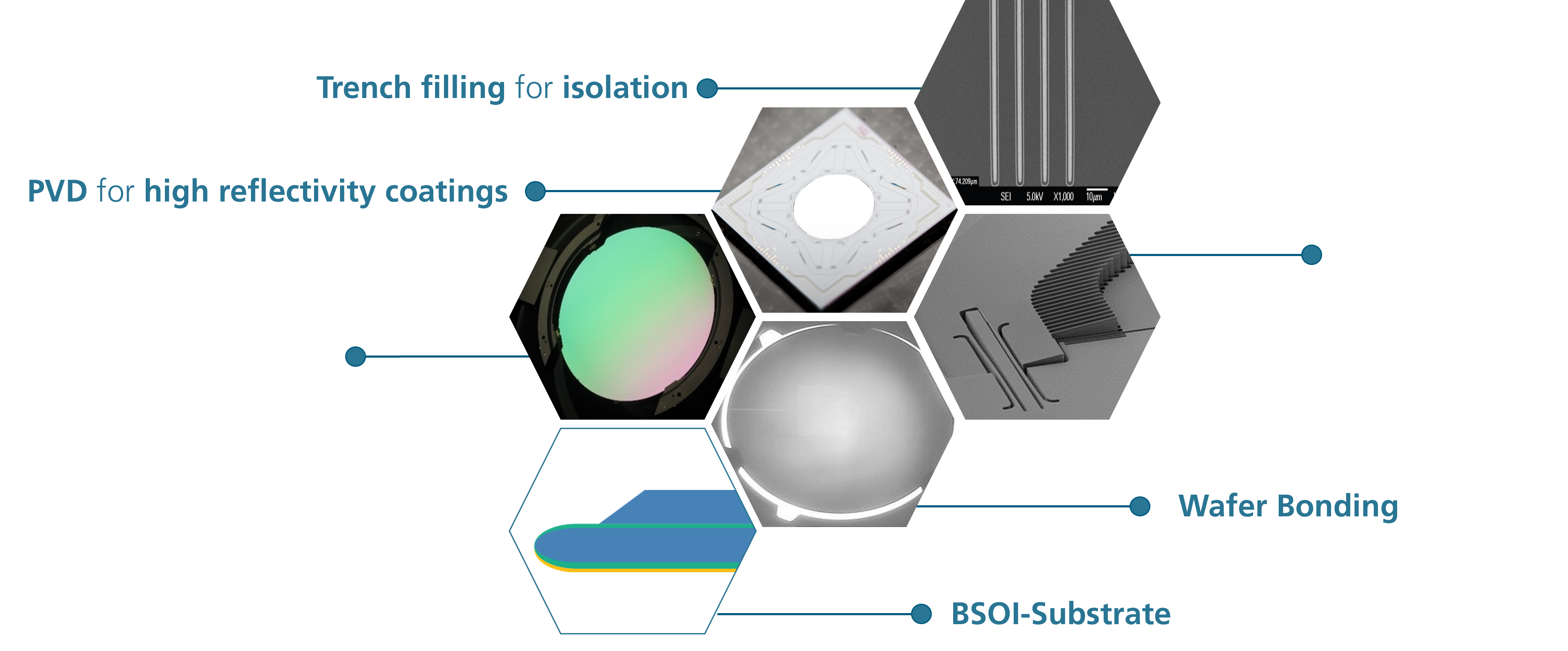

Our offering includes both complete processes and specialized individual processes to meet the most diverse requirements in MEMS, microdisplay and CMOS production, from front-end to back-end-of-line.

Our overall processes include surface micromachining, bulk micromachining and monolithic MEMS-on-CMOS integration as well as active silicon/electronic devices (CMOS).

In addition, we offer a wide range of individual processes, including in particular silicon deep etching, various depositions (CVD to ALD), wafer bonding, dicing & packaging and inline characterization.

With state-of-the-art technology and an experienced team, we guarantee the highest quality and reliability in every step of the production process.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems