Substitution of N-Methyl-2-pyrrolidon (NMP)

N-methyl-2-pyrrolidone (NMP) has proven to be an essential material for lift-off processes and resist removal in cleanroom semiconductor manufacturing. This chemical enables precise structuring of thin films and cleaning of surfaces, which is particularly important to ensure the quality and performance of semiconductor devices

As of 2018, NMP has been included in Annex XVII of the REACh Regulation due to its reproductive toxicity and irritant effect on eyes, skin and respiratory tract. Since May 2020, consumer products with an NMP content of 0.3% or more have been banned in the EU.

At Fraunhofer IPMS, we focus on the development of processes using safer products. Our research aims to identify and investigate substitutes for NMP.

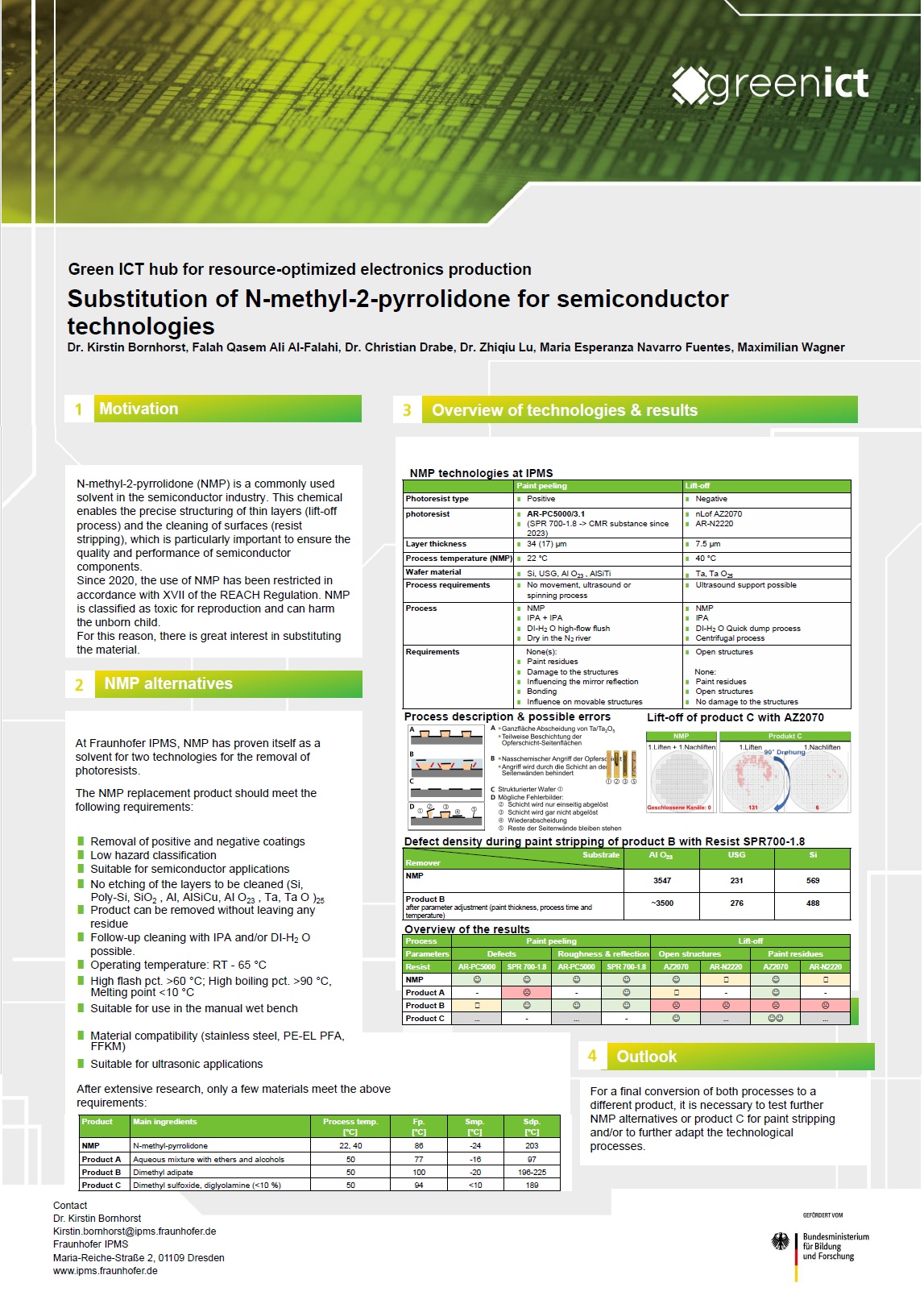

The replacement product for NMP should meet the following requirements:

- Removal of positive and negative varnishes

- Low hazard classification

- Suitable for semiconductor applications

- No etching of the layers to be cleaned (e.g. Si, Poly-Si, SiO2, Al, AlSiCu, Al2O3, Ta, Ta2O5)

- Residue-free removal

- Follow-up cleaning with IPA and/or DI-H2O possible

- Application temperature: room temperature up to 65 °C

- High flash point (>60 °C), high boiling point (>90 °C), melting point (<10 °C)

- Suitable for use in manual wet benches

- Material compatibility (stainless steel, PE-EL, PFA, FFKM)

- Suitable for ultrasonic applications

Three possible products have been identified as potential substitutes for NMP:

- An aqueous mixture with ethers and alcohols

- A product based on dimethyl adipate

- A mixture of dimethyl sulfoxide and diglyolamine

More detailed information can be found in the poster on the left.

Fraunhofer Institute for Photonic Microsystems

Fraunhofer Institute for Photonic Microsystems